ArtiLink Series

1. Function Usage

1.1. ArtiLink300 Automatic Reset Reason

The ArtiLink 300 may automatically reset when subjected to strong electrostatic interference. This is a normal response.

1.2. Why ArtiLink400 Cannot Clear DTCs

Please ensure that the faults related to the DTCs have been properly repaired. Next, turn off the ignition switch. Wait for 1-3 minutes, then start the vehicle. Finally, try running the "Read Codes" function again. (Some DTCs can only be cleared this way.)

1.3. ArtiLink500B Fault Code Reading Process

Fault Code Reading Process:

- After entering the vehicle diagnostic system function, the diagnostic tool will automatically communicate with the vehicle's computer to determine the communication protocol. Once confirmed, the connection is established.

- To read the fault codes, select the "Read Codes" option and briefly press the [OK] button. The diagnostic tool will communicate with the ECU and display the fault codes.

1.4. ArtiLink500B Clear Fault Codes

Select the "Erase Codes" icon and briefly press [OK]. The procedure to clear fault codes should be performed after completing the necessary repair work. Once confirmed, the emission-related data stored in the ECU will be reset or cleared and cannot be recovered.

*Do not start the engine while clearing fault codes.

1.5. Can AL500B Detect the Battery Installed in the Vehicle?

The AL500B product supports both in-vehicle and out-of-vehicle battery testing.

1.6. What types of batteries can the AL500B test?

The AL500B is suitable for 12V standard liquid batteries, AGM flat plate batteries, AGM spiral batteries, GEL batteries, and deep cycle batteries, with CCA values ranging from 100 to 2000.

1.7. How can I determine if my vehicle's battery is good or bad?

The battery tester will display SOH (State of Health), SOC (State of Charge), CCA (Cold Cranking Amps), voltage, internal resistance, and rating. The tool provides test results indicating whether the battery is "Good" or "Bad" for your reference. If the internal resistance is too high, the battery is damaged and needs replacement.

1.8. What is the purpose of the extra connector on the diagnostic cable? / What is the shorter branch on the OBD2 cable used for?

The extra connector on the AL500B diagnostic cable is a DB15 Male connector. Some older vehicle models with OBD ports that do not supply power require the DB15 Male connector to connect to a DC power source. Newer vehicle models do not require this.

1.9. AL Series Vehicle Function Coverage

- The AL series products only support vehicles equipped with an OBDII diagnostic interface (16-pin OBDII interface). They do not support 24V commercial vehicles, motorcycles, or pure electric vehicles.

- The implementation timeline for OBDII mandatory regulations varies by country: USA 1996, European gasoline vehicles 2000, European diesel vehicles 2004, Japan 2002, South Korea 2007, and China 2008; Annotation[A2]: EU diesel vehicle 2004

- Whether the device supports OBD diagnostics for a vehicle can be determined by the vehicle's VIN or model year, which can be checked via the following link: www.vindecoderz.com.

1.10. Is JOBD Supported?

- Japanese vehicles sold domestically in Japan gradually introduced JOBD (Japanese OBD) starting from 1998. Although JOBD is largely compatible with OBDII, its functionality is slightly different.

- For vehicles in the Japanese market post-2002, most support emission-related standard OBDII data, but some advanced features or manufacturer-specific data may only be supported by JOBD, which cannot be read by OBDII code readers.

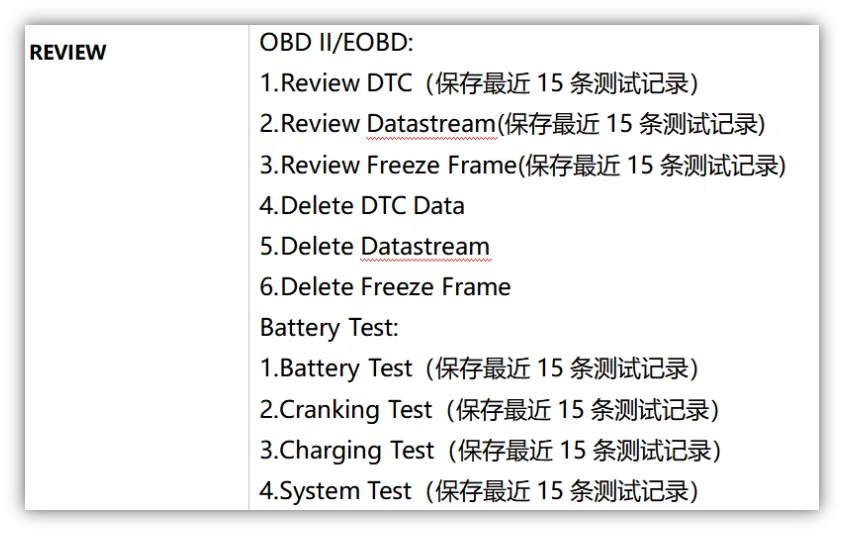

1.11. AL500B supports the amount of historical data storage

Refer to the image below

2. Download Update

2.1. Looking to download the client program to upgrade AL500B, is there an installation package compatible with Apple computers?

We regret to inform you that we currently do not have an installation package compatible with MacOS, only Windows.

2.2. How to download and upgrade ArtiLink600

ArtiLink update process:

- Install the memory card into the provided adapter and insert it into the computer's USB port.

- Reopen the update tool.

- Select the update content you need, then click [Download] to download the update package to the memory card.

- Insert the memory card with the downloaded update package into ArtiLink600.

- Power the ArtiLink600 via USB cable.

- ArtiLink600 will verify the update files on the memory card, and if a new version is detected, it will automatically start updating.

2.3. How to obtain the registration code and update

- You can enter 【INFO】 on the device's main interface to view the registration code (using AL500 as an example);

- For product updates, please refer to the following YouTube video link: https://www.youtube.com/watch?v=r6dUSnP6fgQ&list=PLqOSDuCI2DNeCeECzOFQ9uGyBUGsmv5wl&index=2

3. Fault Issue

3.1. ArtiLink500 vehicle system stops when reading data stream.

This may be due to a poor connection. Please turn off the tool, reconnect the cable, and then start the vehicle again.

3.2. ArtiLink500 is unresponsive when communicating with the vehicle's computer.

Please confirm the power voltage and check if the throttle is closed, if the transmission is in neutral, and if the water temperature is appropriate.

3.3. ArtiLink500 I am having difficulty clearing the fault codes. What should I do?

- Please ensure that the faults related to the fault codes have been properly repaired.

- Turn off the ignition switch. Wait for 1-3 minutes, then start the vehicle. After that, try running "Read Fault Codes" again. (Some fault codes can only be cleared this way.)

3.4. ArtiLink500B tool system stops/freezes when reading data stream. What should I do?

This may be due to a loose connector, please unplug and reinsert the connector.

3.5. ArtiLink500B Why does the screen flicker when igniting?

It may be caused by electromagnetic interference, which is normal.

3.6. ArtiLink500B Why are there so many fault codes?

This may occur in cases of poor connection or grounding faults.

3.7. ArtiLink500B Why can't I clear the fault codes?

Ensure that the faults related to the DTCs have been properly repaired. Then, turn off the ignition switch. Wait for 1 to 3 minutes, start the vehicle. Try running "Read Fault Codes" again to see if the issue is resolved. Some DTCs can only be cleared after completing all these steps.

3.8. ArtiLink600 What to do if the screen flickers or the font is corrupted when using the scanner?

This issue can be resolved by following these steps:

- Insert the memory card into the scanner, then connect the scanner to the computer via USB cable.

- The system will automatically upgrade the firmware and restart.

3.9. ArtiLink600 What to do if the scanner fails to start?

Please connect the scanner to the computer via USB cable to fix the firmware.

3.10. ArtiLink600 is unresponsive when communicating with the vehicle computer.

Please confirm if the power voltage is normal, and check if the throttle is closed, if the transmission is in neutral, or if the water temperature is appropriate.

3.11. ArtiLink600 When using the PC tool for registration, it prompts for a registration code, where to get it

- The activation code is in the device's Help -> Tool Information;

- The main page of the AL600 device when powered on also displays it.

3.12. Abnormal after update

- Close or uninstall, reinstall the PC side, and perform the software update again;

- Try another Windows computer;

- If the problem persists after the above steps, please briefly describe the abnormal situation, and it is recommended to provide video evidence, we will use this as proof to reissue the product for you.

3.13. ECU communication failure

- Confirm if the vehicle supports the standard OBDII protocol;

- Reconnect the OBD diagnostic line connected to the car and try to check if the actual position of the pins in the vehicle's OBD interface has retracted due to multiple insertions and removals of the diagnostic device.

3.14. Oxygen sensor and vehicle monitoring test not supported

- Some vehicles, although compliant with the OBDII standard, do not fully implement all OBDII modes (such as Mode$05 or Mode$06). Especially earlier or some special-purpose vehicles may not provide oxygen sensor test data or detailed vehicle monitoring test results;

- Of course, if other devices can read normally through OBDII function, but ours cannot, it is likely that our device has a problem, please provide the vehicle VIN, upload data for backend analysis.

3.15. Unable to Clear Codes

The prerequisite for clearing fault codes is that the cause of the vehicle's fault has been addressed (either through hardware repair or software adaptation). If the fault codes cannot be cleared, please provide the following information:

- Specifically, which system and what fault code;

- Provide the SN, vehicle model information, year, model, and VIN; Note[A6]: AL series products cannot upload logs.

- How the fault occurred and what abnormal phenomena the vehicle exhibited;

Once we obtain this information, our professional team will conduct a preliminary analysis and provide you with a professional response. The more comprehensive the information provided, the more accurate the response will be.

4. Feedback and Suggestions

4.1. Why is there no LED light

We have upgraded the equipment, and the new version of the OBDII cable does not have an LED light.

Related Articles

Phoenix series basic operations

1. How to upload diagnostic log on the scanner? Backgroud: When there is error/abnormal message pops up when performing diagnostic function, you are advised to upload the log, and then send your problem description and device SN to ...Phoenix Series

Phoenix Max 1. Function Usage 1.1. How to Upload Logs Click FEEDBACK in the main menu > Select vehicle brand > Choose feedback log file, select issue type... > Enter upload/submit 1.2. Can I use a charger of the same type to charge my tablet? No, ...ArtiDiag Series

UltraDiag 1. Function Usage 1.1. Do I need to upgrade the firmware before using UltraDiag for the first time? Yes, once the UltraDiag VCI is connected to your UltraDiag tablet via Bluetooth, the firmware will automatically update to the latest ...Thermal Imaging Series

1. Function Usage 1.1. How to Properly Connect a Handheld Device to TDView and Then Open It ● For four-digit system versions, you need to enable USB connection first and then connect to the computer. ● For three-digit system versions, connect ...OEM Dongle Series

RLink Lite 1. Function Usage 1.1. Is power supply required when binding RLink Lite? There are two methods for binding: using the Rlink platform (Driver Monitoring System) or binding through the RLink Lite's own interface. Power supply is required ...